Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

Waste Heat Recovery Systems: How Factories Reduce Energy Costs

Jan 27, 2026In the current industrial landscape, energy costs often dictate the thin margin between profit and loss. Many factories unknowingly vent staggering amounts of thermal energy through exhaust stacks and wastewater discharge. At GlobalVentFans (DYY), our engineering focus is on closing this loop. By integrating a Waste Heat Recovery System (WHRS), facilities can recapture "lost" heat to power other processes, directly impacting the bottom line while meeting modern sustainability goals.

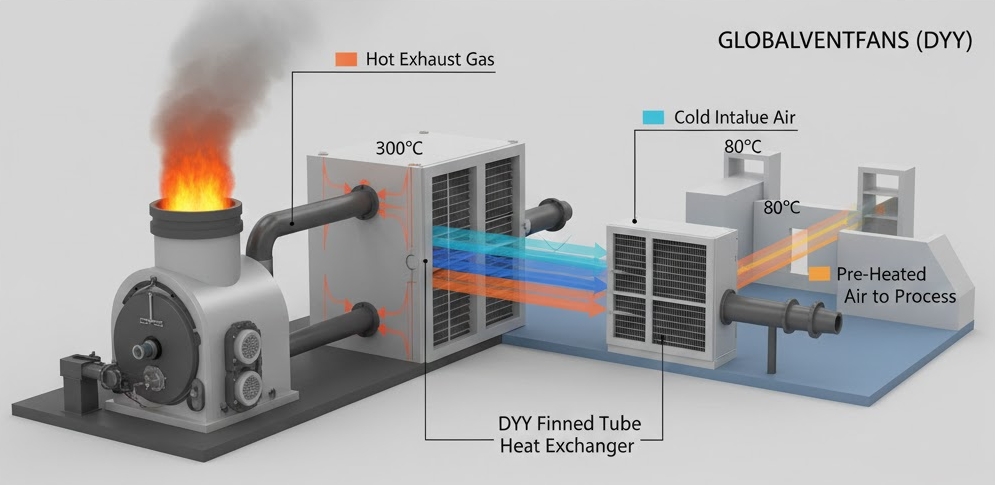

A high-performance WHRS acts as a thermal bridge. The most effective systems utilize a Finned Tube Heat Exchanger to facilitate this transfer:

The Physics of High-Efficiency: Transfer Our engineering team prioritizes the "Fin Efficiency Factor."Unlike standard heat exchangers, DYY utilizes a specialized mechanical expansion process to ensure a 100% gap-free bond between the fin and the tube. This eliminates air pockets that act as thermal insulators, ensuring that the recaptured heat is transferred with minimal loss, even in high-velocity airflow environments.

Building a durable recovery system requires a deep understanding of thermodynamics and material science. Our approach at our 115,000m² Foshan facility is built on decades of practical application:

Advanced Manufacturing in our Foshan Hub Operating out of a 115,000m² facility allows us to maintain a fully closed-loop production cycle. To complement our G2.5 dynamic balance testing, we utilize CNC laser cutting for fin profiles to ensure aerodynamic consistency. This level of manufacturing precision is why our waste heat recovery components maintain structural integrity under the constant thermal expansion and contraction cycles typical of industrial boilers and kilns.

To achieve the highest ROI, a waste heat recovery system must be fine-tuned to the specific physics of the facility. At GlobalVentFans, we consider variables that generic suppliers often overlook:

For many B2B buyers, the barrier to upgrading is the fear of long downtime. We have optimized our production cycle in Foshan to address this:

Reliability Across 70+ Countries Global trade requires more than just a quality product; it requires logistical and regulatory expertise. Our systems are not only built to CE, CCC, and SASO standards but are also documented with comprehensive technical datasheets to simplify local compliance audits. To safeguard your investment, we provide reinforced packaging designed for long-distance maritime transit, ensuring that the precision-aligned fins arrive at your site in factory-perfect condition

Efficient waste heat recovery is an investment in long-term operational stability. By leveraging the manufacturing precision and material expertise available at GlobalVentFans (DYY), factories can transform their exhaust from a waste product into a valuable resource.

Q1: How much energy can a factory realistically save with a WHRS?

A: Depending on the exhaust temperature and flow rate, most industrial facilities see a reduction in fuel consumption between 10% and 25% by pre-heating combustion air or boiler water.

Q2: Is the system difficult to clean if the exhaust contains dust or oil?

A: We engineer our finned tube pitch specifically to accommodate "fouling factors." By adjusting the gap between fins, we ensure the system can be easily cleaned with compressed air or high-pressure water without damaging the structure.

Q3: Can GlobalVentFans customize systems for different power grids?

A: Yes. We provide full OEM/ODM motor customization, supporting various voltages and frequencies (e.g., 60Hz for the Philippines or 50Hz for Europe) to ensure seamless VFD integration.

Hi! Click one of our members below to chat on